from the umbel to the glass

It’s a long process until a fresh Hofbräu beer bubbles in the bottle or flows from the tap into the glass. At the beginning are hops, malt, yeast and water. This is what the German Purity Law stipulates and according to which we have been working for more than four hundred years at Hofbräu München. The unique Consumer Protection Act of 1516 is not only the standard but also seal of approval for the quality of our beers. In addition, we accept only the best and controlled quality when purchasing the ingredients for our beers. We gladly source from regional suppliers or rely on our own production. What this claim specifically means can best be demonstrated by our four raw ingredients.

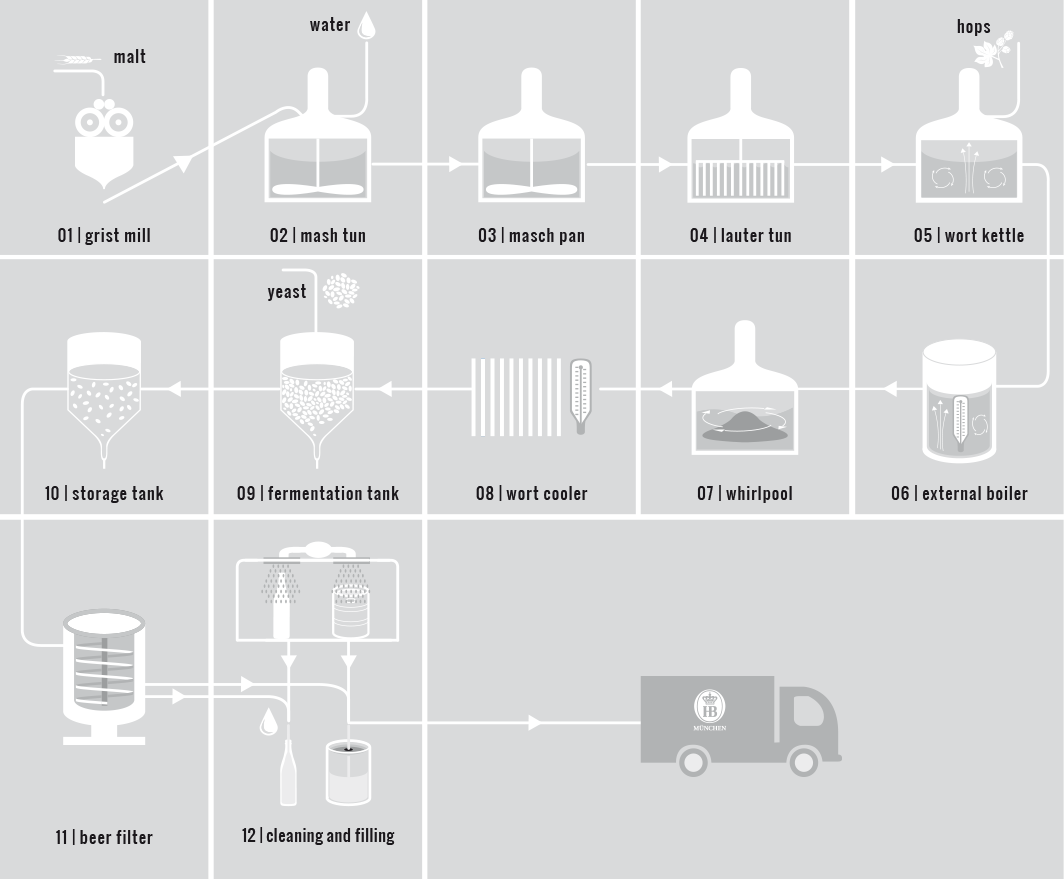

From the grist mill to bottling: In twelve steps to beer

Our graphic explains how the raw ingredients hops, malt, yeast and water create a fine Hofbräu beer.

- The malt grains are milled in a grist mill. They can then be processed further in the brewhouse.

- The milled brewing malt is mixed with water in the mash tun (in the technical jargon: “mashing”) and heated. This dissolves the starch from the malt and breaks it down into fermentable sugars.

- From the mash tun, so-called partial mashes are removed and cooked in a mash pan. In this process, the flour body components of the malt are physically digested. With the help of a pump, the partial mashes are returned to the mash tun. This intermediate step allows enzymes to better affect and break down starch.

- In the lauter tun, the husks of the malt grain (husks) and other insoluble ingredients separate from the wort.

- The hops are added. In the wort kettle, wort and hops are then cooked together.

- In the external boiler, the wort of hops, malt and water are boiled for about an hour. This causes excess water to evaporate and certain volatile substances to be expelled. The process also sterilizes the wort, inactivates enzymes and allows the protein to clot (protein precipitation/flocculation).

- The wort is set in rotation by a tangential inlet in the same vessel. Due to the rotational movement, the remaining protein coagulates in a compact cone with ‘hot break’ in the middle of the so-called whirlpool. After about 30 minutes of standing time, the so-called cast wort is removed in the direction of cooling. The hot break remains in the cooker.

- In the wort cooler, the wort is cooled down to cellar temperature depending on the type of beer.

- In the fermentation tank, the brewer’s yeast is added, and the fermentation process starts. During this, alcohol and carbon dioxide are produced from the fermentable sugars of the wort. The fermentation with bottom-fermenting yeast takes place at temperatures between 7 and 9 degrees Celsius and lasts roughly six to seven days. The yeast then settles at the bottom of the tank. Top-fermenting yeast ferments the wort in 4 to 5 days at 18 to 20 degrees Celsius and subsequently rises to the surface.

- After completion of the main fermentation, the yeast is removed from the tank. The resulting “young beer” is stored until maturity at around 0 degrees Celsius for several weeks in the storage tank.

- Using a beer filter, the bottom-fermented beer is filtered and placed in pressure tanks until filling.

- The finished beer is filled in barrels or bottles. Barrels are first cleaned outside and inside. After filling the beer barrels are stored on pallets. Beer bottles are, of course, also cleaned and checked. After bottling, they receive a closure, are labelled and then packaged. Ready for transport, our beer is now ready to be enjoyed all over the world!